Soda Ash Substitute Agent SF-310

Used in dipping dyeing process by Reactive Dyes. To substitute the Soda Ash, trisodium phosphate (TSP), caustic soda. Can reduce the cost of Soda Ash in Dyeing Process. And get levelling dyeing effect.

Typical Data:

| Appearance | White powder |

| Composition | Buffer Organic alkali |

| pH value(1%water liquor) | 12-13 |

| Solubility | Easily soluble in cold water |

Properties:

The applicantion amount is about 1/7-1/10 of the Soda Ash. Won’t lumping in the bath and pipe to prevent pollution again.

Excellent fixing property. Promote dye fixing and improve the rubbing fastness and color brightness when used in cellulose fiber dyed by reactive dyes.

Excellent levelling property and repeatability, especially suitable for dyeing by turquoise blue, grass green and sweet dyes.

No different in bathes and lots.

Can be used in variety dyeing equipment, especially suitable for the equipment which include feeder liquor autmatic systen and dyeing cheese in low bath ratio.

Washing fastness is better than fixing by Soda Ash.

Application:

I. The applicantion amount is according to the dye systen, the general suggest amount is 1-4g/L.(Or diluted SF-310 at SF-310: water =1:7 –1:10, then use the same application amount as Soda Ash. ) Please make the trail first. According to the experience of most dyeing factories, compare with Sode Ash, the dye fomula should reduce Yellow, add little Red. And can save dyes.

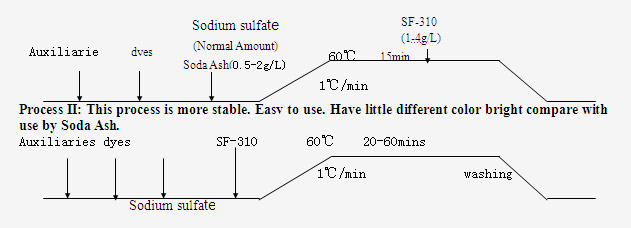

II. Dyeing curved line is reference as follows:

Process I: The Color bright is nearer use by Soda Ash when according this suggested process.

Packing & Storage: 25 Kg/plastic woven bag lined with plastic bag; Avoid deliquescence, must sealing up the vessel and stored under cool and dry conditions.

Notice:

I It is a Strong alkaline product, and causticity. Should pay attention to safe protection when use. If stained with skin or eyes, please wash by large amount of cold water immediately.

II Fixing Alkali SF-310 is the buffer organic alkali used in fixing by reactive dyes, can use Soda Ash.

III When dye the dark color, can add more suitable Sodium Sulfate amount (about 8-12g/L) or pre-add 0.5-2g/L Soda Ash before add the dyes to solve the problem that middle and dark color get little light color

IV In the all dyeing process, Fixing Alkali is steadier to control, better dye repeatability.